When developing an electrical product that must comply with a UL product safety standard, selecting the right plastics is very important. Most product developers are aware that plastics must be UL certified with a flammability rating. See Weekly Whitepaper #68 for details on UL flammability rating of plastics and the related objectives with plastic enclosures and fire containment.

While identifying the proper flame rating is very important, selecting a plastic that will meet the requirements applied to your product is much more than just selecting a material with the proper UL flame rating. There are other UL plastic ratings that must be considered when sourcing your plastics.

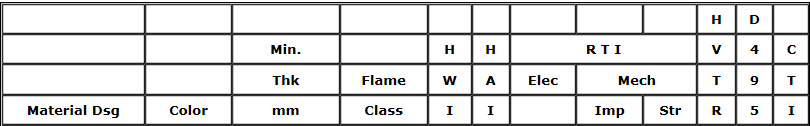

UL Plastics - Common Ratings

This is the header for a UL plastics certification card. It is important to understand which of these ratings are required based on your plastic applications.

Other UL Plastic Rating Considerations:

1) Color: It is very important to identify the colors associated with the desired flame rating. Many materials have different flame class ratings based on material color = some color additives have more of an effect on flammability than others. Be sure your plastic color is UL certified for the flame class rating you need. For maximum flexibility with future product color variations, you may want to select a plastic that is UL certified for “ALL” colors.

2) Minimum Thickness: All UL flame class ratings have a minimum material thickness that must be provided for that flame rating. It is important to identify the minimum material thickness associated with the flame rating. Many materials have multiple flame ratings based on varying material thickness = increased thickness for increased flammability rating. At the minimum material thickness used in your product, what is the UL flame class rating for the plastic?

3) Hot-Wire Ignition (HWI): An HWI rating may be required if the plastic is used in contact with a part that becomes extremely hot, so hot that the plastic could ignite. The HWI rating identifies a materials resistance to ignition under such conditions. The rating indicates the mean time to ignition of the plastic when in contact with an extremely hot component.

4) High-Current Arc Ignition (HAI): The HAI rating is applicable to plastics used as insulating materials where high current arcing is possible. When used as an insulator, the plastic material may be in proximity to arcing parts during normal or abnormal operation. The HAI rating helps differentiate performance between plastics with regard to resistance to ignition from high-current arcing electrical sources. If the intensity and duration of the arcing is severe, the insulating material can ignite. The HAI rating identifies the mean number of arcs required to cause ignition.

5) Relative Thermal Index (RTI): The RTI is the temperature rating of the plastic. There are 3 subcategories of RTI that must be considered depending on the application of the plastic and the product. A plastic can have one or more of the following ratings – be sure to select a plastic that has the appropriate RTI based on the application of the plastic and the temperatures the plastic will be exposed to in your product.

a) Electrical RTI – when insulating properties of the material are depended upon.

b) Mechanical Impact RTI – for applications that involve mechanical strength with impact resistance, toughness, elongation, and flexibility considerations.

c) Mechanical Strength RTI – for mechanical strength and structural integrity where impact resistance, resilience, and flexibility are not applicable.

6) High-Voltage-Arc Tracking (HVTR): The HVTR rating is also an arc ignition rating. The HVTR rating is used to determine a plastic material’s resistance to ignite or form a visible carbon path over the surface of the material when subjected to high-voltage, low-current arcing. The HVTR rating is expressed as the distance of the conductive path developed over time (mm/min). The primary purpose of the test is to demonstrate the ability of an insulating material to be subjected to repeated arcs over the surface of the material without developing a carbon path – a situation that can occur as a result of overvoltage transients on the mains power.

7) High-Voltage, Low-Current-Arc Resistance (D495): The D495 rating is also an arc ignition rating established through testing to the standard ASTM D495. The D495 rating is similar to that of the HVTR rating except that the D495 rating is expressed as the number of seconds that a material resists the formation of a conductive path as a result of high-voltage, low-current arcs.

8) Comparative Tracking Index (CTI): The CTI rating is the international rating for arc ignition resistance, established through testing to the standard IEC60112. With CTI, the high-voltage, low current arc is induced and the maximum voltage which the test specimen can withstand without breakdown is used to establish the CTI rating.

Conclusion

Be aware of all the UL ratings required and choose your plastics wisely.